At Hind Defence Equipment Private Limited disassemble ammunition by separating the different components such as fuze, boosters, primers etc from cartridge cases for attaining an eco-friendly and sustainably healthy environment.

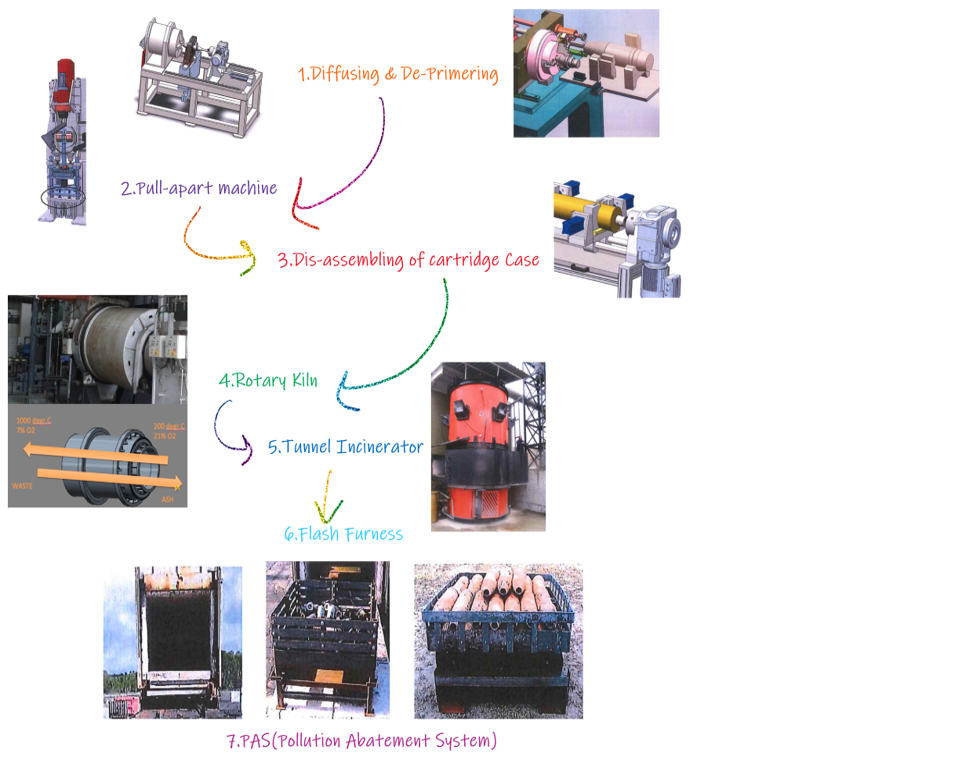

We use the process of ammunition defusion by removing the primer with the help of highly equipped automatic machines. Once the primer is removed, extraction of propellant cartridge from the round is done with the help of pull apart machine, eventually disassembling the cartridge case.

Ammunitions are further cut through Band saw cutting machine. A Rotary kiln is used instead of Static Detonation Chamber (STD) which are also used for extracting and finely dividing the subparts of ammunition. Then it is sent to a static oven called Tunnel Incinerator and at the end sent to Flash Furness for extracting metals through melting

Once the separation is performed the metals are reused and the residual is burnt leading to very minimal harm for the environment which is only possible with our highly advances equipped machines